Product brief:

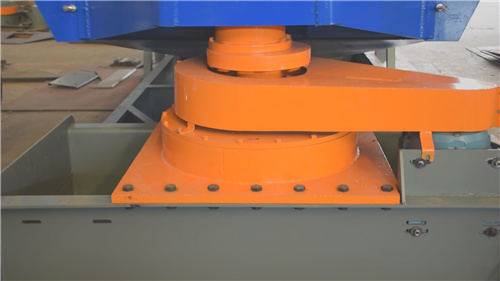

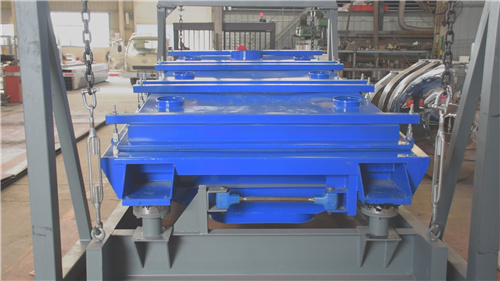

Gyratory sifter is a kind of high efficient screening equipment with large output and high screening accuracy. It has self cleaning system and avoid clogging. The quick release clamp make the mesh change easily and quickly. There are multi inspection port on the top of screen box for conveniently checking the material flow and screening condition. The discharging spout can be designed on the bottom or on the end of screen box according to your demand.

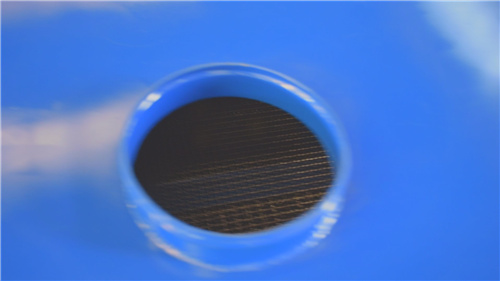

The unique mesh frame design provide convenient and fast change course. It save downtime and labor cost. One machine can be designed multi layer and the production capacity also become double.

There is no vertical vibration during the whole reciprocating motion, so the material can constant contact the screen surface. There is less wear and loss for the material, so it have long service life compared with ordinary vibrating screen.

Features

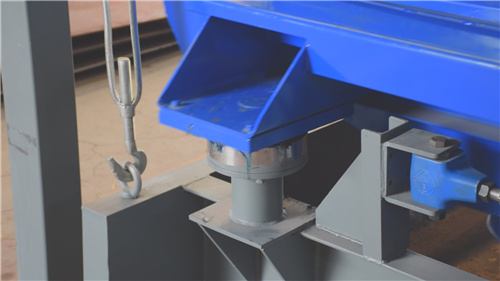

Low demand for conveying equipment elevating height because it’s feed port is lower.

Every layer take cleaning device which proof clogging when sieving.

The headroom required is low for the installation space and it is easier for maintenance.

Full seals ensure the operator and environment again the dust and meet the friendly environment demand.

Technical parameters

|

Model |

BFY-1230 |

BFY-1236 |

BFY-1536 |

BFY-1836 |

BFY-2040 |

|

Screen Size(mm) |

1200×3000 |

1200×3600 |

1500×3600 |

1800×3600 |

2000×4000 |

|

Material Granularity |

6mm – 0.075mm |

||||

|

Angle |

5°-8° |

5°-8° |

5°-8° |

5°-8° |

5°-8° |

|

Layer |

1-5 |

1-5 |

1-5 |

1-5 |

1-5 |

|

Power |

4kw |

4kw |

5.5kw |

7.5kw |

7.5kw |

Application

chemical, metallurgy, ferrous metal, non-ferrous metal, food and abrasive, especially for screening heavy alkali, salt, resin, fertilizer, urea, feed, reduced iron powder, zirconium oxide,ceramic, barite and etc.